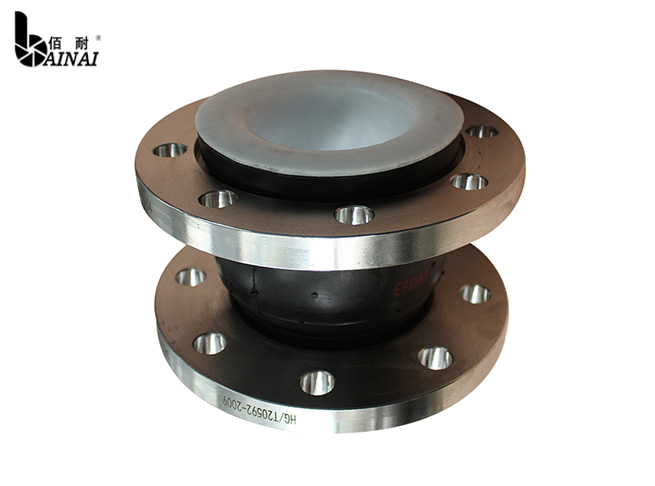

PTFE (Polytetrafluoroethylene) lined rubber expansion joint is a specialized flexible connector designed for use in piping systems that handle corrosive or aggressive media. It combines the flexibility of rubber with the chemical resistance of PTFE, making it suitable for demanding applications.

| Nominal diameter |

Length (mm) |

Axial displacement | Horizontal movement (mm) |

Deflection angle (a1+a2) |

||

| mm | Inch | Compression (mm) |

Extension (mm) |

|||

| 32 | 1¼ | 95 | 9 | 6 | 9 | 15° |

| 40 | 1½ | 95 | 10 | 6 | 9 | 15° |

| 50 | 2 | 105 | 10 | 7 | 10 | 15° |

| 65 | 2½ | 115 | 13 | 7 | 11 | 15° |

| 80 | 3 | 135 | 15 | 8 | 12 | 15° |

| 100 | 4 | 150 | 19 | 10 | 13 | 15° |

| 125 | 5 | 165 | 19 | 12 | 13 | 15° |

| 150 | 6 | 180 | 20 | 12 | 14 | 15° |

| 200 | 8 | 210 | 25 | 16 | 22 | 15° |

| 250 | 10 | 230 | 25 | 16 | 22 | 15° |

| 300 | 12 | 245 | 25 | 16 | 22 | 15° |

| 350 | 14 | 255 | 25 | 16 | 22 | 15° |

| 400 | 16 | 255 | 25 | 16 | 22 | 15° |

| 450 | 18 | 255 | 25 | 16 | 22 | 15° |

| 500 | 20 | 255 | 25 | 16 | 22 | 15° |

| 600 | 24 | 260 | 25 | 16 | 22 | 15° |

1.Chemical Resistance: The PTFE lining provides excellent resistance to a wide range of chemicals, acids, and solvents, protecting the rubber from degradation and ensuring the joint's longevity.

2.Flexibility: The rubber component allows for significant axial, lateral, and angular movements, effectively absorbing thermal expansion, vibrations, and misalignment in the piping system.

3.Temperature Tolerance: PTFE can withstand a wide range of temperatures, allowing the expansion joint to function effectively in various thermal conditions.

4.Reduced Friction: The smooth surface of the PTFE lining reduces friction, allowing for better flow characteristics and minimizing wear on the joint.

PTFE lined rubber expansion joints are commonly used in industries such as chemical processing, pharmaceuticals, food and beverage, and wastewater treatment. They are ideal for applications involving corrosive substances, high temperatures, and where both flexibility and chemical resistance are critical. These joints help protect the integrity of the piping system while allowing for movement and vibration absorption.